|

|

|

|

The main choices under

facade refurbishment include; repair, insulate, over

clad and reconstruct.

With much of the stock

of tower blocks originating from the 1960’s and

1970’s in the UK., the building fabric of blocks

would likely have required some refurbishment. The

state of the building fabric would be influenced by:

- the quality of the construction – either defined

by the workmanship of the original construction or

by the design of its detailing

- the maintenance and repair policy of the building

landlord

- the extent of vandalism imposed on the block

Undertaking a building condition survey, which would

define the state of the exterior of the building, is

important to undertake at the beginning of any

refurbishment. Obtaining comments from tenants as to

their observations of conditions is an additional

means of detecting building defects. |

|

|

REFURBISHMENT OPTIONS |

|

Basic |

|

■

Overcladding

■

Add thermal insulation

■

Replace windows

■

Provide trickle vents

■

Provide

draught stripping |

|

Good |

|

■

Provide

solar shading

■

Increase

size of openings

■

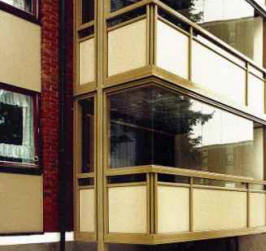

Enclose balconies |

|

Exemplary |

|

■

Install

photovoltaic cladding

|

|

|

|

|

|

|

Overcladding

Overcladding options for tower

blocks include, insulation render and rainscreen cladding.

Rainscreen cladding

This comprises a resilient

outer screen, usually a decorative cladding panel, supported

on a vertically aligned timber, aluminium or steel sub-frame,

which is fixed back to and supported by the primary building

structure. A continuous void is maintained immediately behind

the cladding panel and the entire system is ventilated at

the base and head as well as at all penetrations.

Any moisture penetrating through

the various joints in the cladding can be effectively removed

by the provision of uninterrupted ventilation paths for

the full height of the façade. Insulation and breather membranes

can be incorporated into the cladding system, which provide

the added benefit of eliminating both cold bridging and

interstitial condensation, and enhancing the thermal performance

of the structure.

Rendered finish

This typically has a rigid

slab insulation directly mounted or pasted on the external

surface of the the existing wall with an in-situ decorative

coat of render on the outside.

Other considerations

Disturbance to residents

Overcladding process can take

months to complete and requires the use of scaffolding.

This may become an irritant to the residents in the building.

Noise due to drilling may also become a nuisance. The disturbance

could be minimised by restricting the time period;

providing advance notice to the residents and providing

alternative accommodation as retreats.

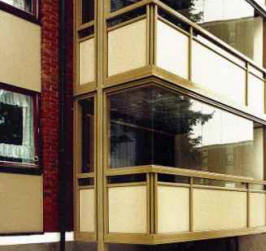

Balconies

Balconies and walkways can

be fully enclosed to create buffer zones. If external wall

insulation is not considered then enclosing the balconies

etc. will also reduce the effect of the thermal bridges

associated with them.

Vandalism

External wall surfaces are

prone to vandalism and graffiti. A more robust cladding

may be required on the ground floor from the one above.

Maintenance

Some overcladding systems

require frequent maintenance and access platforms need to

be provided. Replacement of purpose-made parts may be expensive.

Provision must be made to monitor the performance of all

overcladding systems over time.

Access to the structure of

the building i.e., columns, beams and slabs may be required

to check for deterioration at regular intervals.

Building Life

Overcladding will not reinstate

the structural integrity of the tower block nor prevent

further degradation in buildings that have a problem with

assembly or production of the existing components. Therefore,

decision to overclad should be taken only after careful

investigation of the existing condition. Overcladding may

not increase the building life as much as expected [Harrison

et al, 1986]. |

|

|

|

|

|

Benefits

|

|

The benefits external cladding

of tower blocks include;

-

Restoration of existing

facade

-

Extending the life of

the building

-

Improving appearance and

image

-

Provide thermal insulation

& weather-tightness

-

Improve acoustical performance

of the building

-

Lower maintenance cost

-

Preventing pedestrian

injury from falling external surface.

|

| Embodied

energy: Cladding |

|

| Typical Cost |

| □

Timber cladding on existing external walls: £100/m2

- kiln dried

un-treated larch rainscreen cladding; including breather

membrane & fix to existing walls; excludes cost for

repairing existing walls

□

Permarock External Wall Insulation System: £100/m2

□

Aluminium cladding: £200/m2 -£240/m2

□

Galvanised steel cladding: £190/m2 -£220/m2

□

Terracotta cladding: £350/m2 -£400/m2

□

Rannila ‘Nordicon’ Large Panel with Render £160/m2

-All costs

include 70-100mm external insulation

|

| Funding opportunities: |

| □

Energy Savings Trust |

| Also see: |

| □ Wall insulation

□

Innovations in Façade

Technology |

| More information: |

| □

Energy efficient best

practice

□

Harrison et al, 1986,

Overcladding external walls of large panel system dwellings,

BRE Bookshop, Watford, UK.

□

www.bath.ac.uk |

| Suppliers: |

| □ www.eclcontracts.co.uk

□

www.rannila.com

□

www.permarock.com

|

|

To register as a supplier

click here...

|

|

| |

|

Wall

Insulation

The purpose of re-insulation

is to reduce the heat loss in the building. In addition

to smaller heat losses the indoor climate will be improved

at the same time. The indoor climate will be improved because

the insulated outer walls reduce the heat loss through the

fabric retaining inner room temperatures.

The preferred method of insulating facades is externally

[overcladding]. This can be achieved through

Rainscreen cladding

with insulation or insulated render. Overcladding

can also help in reducing thermal cold bridging.

Internal insulation

can be also considered if a thin layer of insulation is

required, as this has an impact on the internal accommodation

area. It can be an economical option. However, whilst

considering internal insulation, the following issues need

to be taken into account:

Internal insulation will make

the building perform like a light weight building [due to

reduced thermal mass] and thus reducing the heating time

lag. This can be an advantage if the heating services are

being updated to an electric heating system from a gas system.

Insulation beyond a thickness

of 150mm is not advised unless convective heat gains are

controlled [e.g., heat recovery ventilation].

Other considerations

Structural

Typically, internal and external

insulation do not add much load [30-60kg/m2] to the

building structure therefore, structural issues should not

be a barrier to its installation.

Removal and reinstallation

of fittings

Disruption to electrical and

plumbing work on the internal surface will need to be considered.

Fittings and services such as, rainwater & overflow

pipes, windows, radiators, water pipes, switches, window

sills, toilet and kitchen fittings will have to be removed

and reinstalled.

Disturbance to residents

Temporary re-housing may be

required especially whilst considering internal insulation.

Heating system

As the heat loss through the

facade will decrease with additional insulation, the capacity

of the heating system will have to be re-assessed.

Planning permission &

regulations

Planning permission may be

required where the building appearance has been changed.

Building regulation on u-value

of walls do not apply for refurbishments and only apply

to areas such as extensions. However, change in fire performance

must be considered.

|

|

|

|

|

|

Benefits

|

|

For a tower block building,

the roof insulation will provide marginal cost savings,

as the heat loss though the roof surface only contributes

about 3-5% of the total heat losses through the fabric.

However it has substantial

impact on the residences on the top floor. Approximately

30 to 40% saving can be achieved for the upper most flats.

Roof insulation can also reduce

cold surfaces, condensation, and mould growth.

|

| Heat

loss through a typical tower block |

|

|

Embodied

energy: insulation |

|

| Typical Cost |

|

60mm internal

insulation

□

Sheep wool: £33/m2

□ Extruded

polystyrene £30/m2

□ polyurethane

boards £13/m2 |

| Funding opportunities: |

| □

Energy Savings Trust |

| Also see: |

| □ Roof insulation |

| More information: |

| □ Energy

efficient best practice

□ Building

green

□ EST:

Insulation solid walls |

| Suppliers: |

| □ Knauf Insulation

□

Kingspan

Insulation |

|

To register as a supplier

click here...

|

|

| |

|

Replace

Glazing

The importance of improving

the thermal performance of windows is well know in the

building industry.

Double glazing greatly enhances

the thermal and acoustical performance of the building.

Window replacement tends to

have a long payback period, however it is a

crucial step when overhauling the thermal envelope of a

structure.

Replacing windows tends to

be laborious

principally because of the difficulty in finding windows

to fit the building’s existing rough openings. There are

three approaches to fulfilling the task:

Secondary glazing:

This involves added an extra

inner layer of glazing. This can improve the insulation

to the same standard as double glazing without replacing

the existing window.

Custom-built frames: This approach involves completely

knocking out the original window frame and starting from

scratch with the rough opening.

Change opening size: This involves removing the entire

existing window and frame and then begin hacking away at

the rough opening to fit a larger standard sized window.

This approach, clearly, only makes sense if the damage or

decay has extended past the confines of the window into

the building its self, in which case cleaning up the rough

opening might as well entail making it appropriate for an

enlarged but standard fitting.

Custom sized glazing: Especially appropriate when

the frame is in good condition, but perhaps, the glass panes

are separating from a warped weather sash, installing

a custom-sized window into an existing frame can be another

alternative. Though the least expensive initially, such

measures are usually short-lived and aesthetically unappealing.

Other considerations

Provide

trickle vents

Trickle vents are small adjustable

ventilation openings to provide controllable background ventilation.

These should be provided whilst replacing windows.

Draught

proofing

Draught proofing of windows

and doors should also be considered. Draughts are caused

by cold air forcing its way through gaps around windows

or doors causing heat loss.

Environmental impact of

frames

Timber framed windows are

the most environmentally friendly. However, durability concerns

require them to be treated or painted which tends to reduce

their environmental credentials. Wood from sustainablely

forested sources must be specified. uPVC and aluminium windows

must be avoided.

Building regulations

The Part L of the building

regulations do not apply to refurbishment works. However,

as major refurbishments to the facade are rarely done and

windows have a lifecycle of 20-30years, it is important to

consider meeting the current U-value [thermal] requirements.

Security

Ground floor windows and those

easily accessible above ground floor, must be successfully

tested to BS 7950:1997 'Specification for enhanced security

performance of casement and tilt/ turn windows for domestic

applications', at an appropriately accredited UKAS test

house, or if otherwise tested must be independently authenticated,

in writing, by a test house suitably approved by UKAS.

Ground floor windows and those

that are easily accessible to entry must have key operated

locks. Where necessary, opening restrictors or similar built-in

mechanisms will be required. |

|

|

|

|

|

Benefits

|

|

□ Double

glazing can improve thermal comfort for the residents

in areas of the rooms near to windows and save energy for

space heating by 25%. It can also result in better noise

insulation.

|

| Heat

loss through a typical tower block |

|

|

U-values:

window

frames [12mm gap] |

|

| Typical Cost |

| □

Softwood timber & uPVC - £120/m2

□

Hardwood & aluminium - £200/m2.

□

Secondary glazing - £60-£100.m2 |

| Funding opportunities: |

| □

Energy Savings Trust |

| Also see: |

| □ Roof insulation |

| More information: |

| □

Energy efficient best

practice

□ www.securedbydesign.com

|

| Suppliers: |

| □ Knauf Insulation

□

Kingspan

Insulation |

|

To register as a supplier

click here...

|

|

| |

|

Increase size of openings & enclose balconies

As the majority of the energy

used in the tower blocks are for space heating, maximising

any ‘free’ heating helps to reduce energy consumption.

In the UK, approximately 1400kWh of solar radiation falls

on every square meter annually and the typical heating requirement

is about 140kWh/m2. Therefore, it’s at least theoretically

possible to completely heat a home using just 10% of passive

solar gains.

Passive solar measures can be applied to existing buildings

to good effect. To maximise passive solar gains the size

of south facing windows of the tower blocks can be increased

to allow more direct radiation in winters [up to 40% window

to wall ratio]. The high thermal mass of the concrete floors

can 'soak up' radiation during the day and release into the

building at night. Windows within 30 degrees either side

of south are most appropriate.

Alternatively, the south facing balconies can be use as

a conservatory. This can provide an extra unheated living

space which also provides significant free solar gains.

However the positive energy gains of a conservatory will

be lost if the space is heated like the rest of the building.

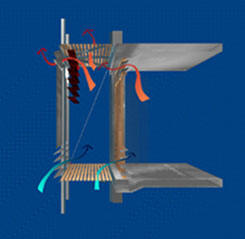

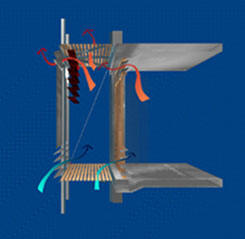

One possible solution is to create an external skin to the

existing façade. The double skin façade captures

heat which can be recovered [at the top] to heat the flats.

Other considerations

Double skin facades:

DTI research on commercial

buildings has shown that double skin buildings are able

to reduce energy consumption by 65%, running costs by 65%

and cut CO2 emissions by 50%, in the cold temperate climatic

prevalent in the United Kingdom when compared to advanced

single skin building. Cost exercises have shown that buildings

employing a double skin may cost as little as 2.5% based

on gross internal floor area.

Over heating

In order to avoid over heating in summer, appropriate shading

devices that permit winter gains but reduce summer gains

are recommended.

Heat loss through glass

In passive solar heating applications, windows should have

a low U-value to reduce winter heat gains and summer conductive

heat gains. Low-E coated double-glazing is recommended.

Controls

A responsive, zoned heating system [which takes into account

passive gains] to automatically cut in when and where necessary

can be incorporated to optimise heating.

|

|

source:

www.bentech.se |

|

|

|

Benefits

|

| |

|

Double

skin facade |

|

source:

Battle McCarthy |

| Typical Cost |

| □

n/a |

| Funding opportunities: |

| □

Energy Savings Trust |

| Also see: |

| □

Add balconies |

| More information: |

| □

Energy efficient best

practice

□ Double

skin facades |

| Suppliers: |

| □ Bentech |

|

To register as a supplier

click here...

|

|

| |

|

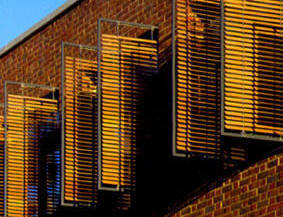

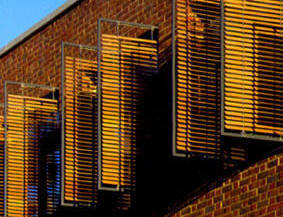

Provide

solar shading

Flats with large windows facing

south, east and west can over heat during summers

due to excessive solar gains.

Horizontal shading devices:

Consider using horizontal shading devices such as, overhangs,

light shelves and external louvres over the windows facing

south. The shading must be designed to let direct winter

gain but must protect against the summer sun.

Vertical shading devices:

These can be used for the windows facing eastern and western

directions.

Overhangs can be solid or

opaque, and use flat or sloped designs. Fixed and movable

exterior louvres running horizontally or vertically across

windows can also be used to reflect and diffuse sunlight.

Fixed and movable interior

features such as drapes, blinds, louvers, and baffles, can

block and reflect direct sunlight entering through windows.

Blinds and curtains also help

reduce heat gains, but generally are not as efficient as

exterior features.

Other

considerations

PV

panels could be mounted on top of the solar shading to generate

electricity. |

|

horizontal overhangs

Vertical louvres |

|

|

|

Benefits

|

| |

| Sun

path diagram: London |

|

| Typical Cost |

| □

|

| Funding opportunities: |

| □

Energy Savings Trust |

| Also see: |

| □ |

| More information: |

| □

Energy efficient best

practice

□

Dutch case study with

solar shading |

| Suppliers: |

| □ |

|

To register as a supplier

click here...

|

|

| |

|

Convert

the lower floor wall into a 'Green wall'

Transforming

the façade of the lower floors of the block into a green

planted wall can be an effective and environmentally sensitive

way dealing with some of the common social and environmental

problems affecting the lower floors of the tower.

Infrequently

accessed service areas at the base of the tower can result

in blank and functional facades that attract anti-social

behaviour such as graffiti, vandalism and create a negative

impression of the tower at the point of arrival. Dwelling

spaces on the lower levels of the tower are often unattractive

to residents due to real and perceived risks from crime,

and there are clear organisational reasons why the ground

floor of the tower has to accommodate at least some service

and plant areas.

Consider

turning the lower floors of the tower into a green façade

as a cost effective way of transforming the image of the

tower and increasing biodiversity while also repelling vandalism.

A green wall can help to integrate the base of the tower into the

surrounding landscape and reduce the visual scale of the

building.

Traditional

wire rope frameworks or metal lattice support systems for

vegetation have a reputation for being expensive and complex

to install and can require a large number of fixings into

the background wall structure. Modular three-dimensional

trellis cladding panels that are pre-assembled in the factory

can have benefits over wire or lattice systems as they provide

their own support structure, potentially reducing the number

of fixings and speeding up on-site installation.

It is

important that the chosen supporting system is of a robust

construction and resistant to climbing. As with all landscape

elements regular maintenance is critical to the success

of the solution and should be considered at the outset.

Installing façade planting systems on lower sections of

the tower simplifies access arrangements and specifying

low-maintenance planting schemes can reduce the maintenance

burden. |

|

|

|

|

|

Benefits

|

-

Cost-effective

way to enhance the appearance of the tower

-

Can reduce

the risk of anti-social behaviour and vandalism

-

Makes

a strong and positive environmental statement and contributes

to local biodiversity

|

| Typical Cost |

| □

n/a |

| Funding opportunities: |

| □

n/a |

| Also see: |

| □ Landscape and microclimate |

| More information: |

| □

www.greenscreen.com |

| Suppliers: |

| □

n/a |

|

To register as a supplier

click here...

|

|

| |

|

Install photovoltaic

cladding

Photovoltaic technology uses light energy to generate

electricity (photo denotes light and voltaic denotes the

generation of electricity).

There are three main types of photovoltaic technologies

available i.e., mono-crystalline [deep blue colour], poly-crystalline

[multi-coloured with sparkling blue tones] and amorphous

[black thin-film].

Mono-crystalline technology is the most efficient however;

it is also the most expensive.

Individual solar cells are interconnected, embedded on glass

or plastic, and framed to form a module. Modules are strung

together in an electrical series with cables and wires to

form a PV array. Direct or diffused sunlight on the solar

cells creates the photovoltaic effect, generating unregulated

DC electric power. This DC power can be used, stored in

a battery system, or fed into an inverter that transforms

and synchronises the power into AC electricity. The electricity

can be used in the building or exported to a mains electricity

company through a grid interconnection.

There are three basic ways

to install PVs on the facade of tower blocks:

Other considerations

Maintenance

PVs do not require much maintenance other than occasional

cleaning of the surfaces to remove dirt and grime [similar

to windows]. However, they must be kept clear of snow, weeds,

and other sources of shading to operate properly. PV cells

are connected in series, so shading even one cell in a module

will appreciably decrease the output of the entire module.

Typically PV have a life of 25 years. The invertors

and batteries have a much shorter life [approximately 3-5years]

and therefore will need regular replacement.

Orientation and Shadowing

The use of PVs on the facade

of the building can only be justified on the south

facing surface.

The orientation and the tilt angle of the PV panels

must be considered relative to the geographical location

of the building site. Typically, in the UK, the panels must

face south at a tilt of about 15 degrees higher than the

site latitude.

Shadowing from nearby buildings and trees will decease

the efficiency of the energy generation. Therefore these

factors must all be taken into account during the design

stages.

Integration to mains

In a typical application,

a building is served simultaneously by the Photovoltaic

and the mains electricity supply. |

|

PV

cladding system, Sandwell

PV

integrated overhangs, Northumbria University

Glass-glass

PV system, Ideal for atriums and enclosed balconies. |

|

|

|

Benefits

|

-

The south facade of a

20-storey tower block with PVs can provide enough to

light most of the common areas within the building.

-

The renewable energy generated

helps reduce 45-60kg of CO2 emissions per year for every

square meter of the PV roof.

|

| Energy

generated |

required |

available |

|

|

| Typical Cost |

|

□

Monocrystalline £920/m2 - £1,440/m2

□

Polycrystalline £550/m2 - £1,300/m2

□

Thin film amorphous £330/m2 - £490/m2

|

| Funding opportunities: |

| □ Solar PV grant

|

| Also see: |

|

□ Wind turbines

□

PV on roof

□

Electrical |

| More information: |

| □ PV-WEB |

| Suppliers: |

| □

Solar

Century |

|

To register as a supplier

click here...

|

|